Contributing to a circular economy

Leveraging partnerships and collaborating along the value chain

In a resource-constrained world that is only 9% circular, we recognize the need to move away from linear “take-make-dispose” models as quickly as possible. We are committed to integrating circular economy principles into our business models considering lifecycle impacts in the markets we serve. We understand that this will require working together across value chains to develop creative solutions that enable a more circular economy that reduces resource needs and reduces waste in all processes of a product’s lifecycle.

The HSE Manager's Guide to Lower Environmental Impact PPE

Key Steps to Help Minimise PPE Waste

Innovation at our manufacturing sites

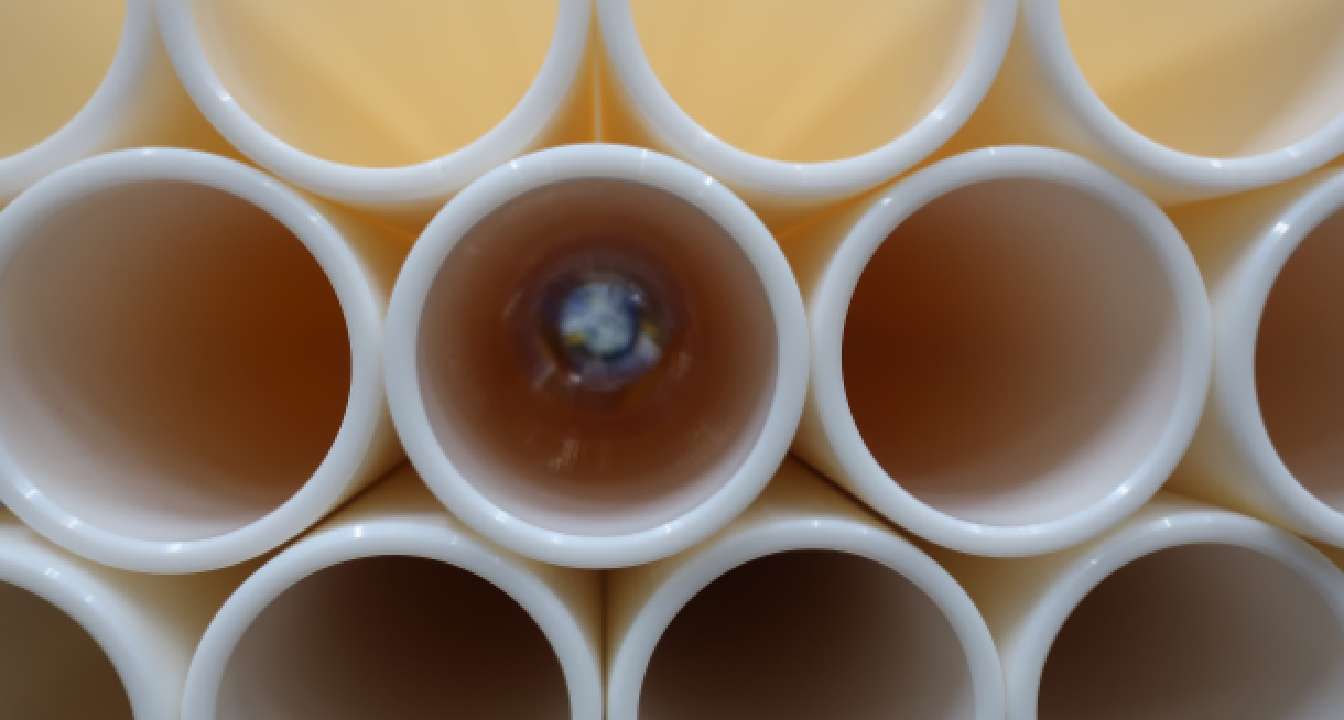

We are making strides in partnering with other innovative companies to upcycle byproduct and turn post-industrial waste from our manufacturing operations into valuable new products. For example, we have an ongoing partnership with Advanced Drainage Systems (ADS) to give Tyvek® production waste a second life as highly engineered water management products.

We’ve also partnered with Gonvarri Steel Services to create a beneficial use of the byproduct (hydrochloric acid) that is created during the manufacture of Nomex® in Asturias, Spain. This not only eliminates the byproduct waste and required neutralization process, it also helps reduce annual water use, electricity consumption and ground transportation associated with Nomex® production.

As we improve our ability to innovate for circularity, we’re continuing to pursue new beneficial uses of byproduct in our operations, while we also improve our ability to avoid the generation of hazardous and non-hazardous waste.

Post-consumer recycling

Tyvek® garments are readily recyclable through the Tyvek® protective apparel recycling program. This service, which is offered for free to qualifying customers within the continental United States, offers the chance to divert garments away from landfills and give them a second life in products like containers, lumber pallets and park benches. DuPont diverts 10 pounds of Tyvek® from the waste stream for every case of 25 coveralls recycled.

<span class="fontsize14">Tyvek® protective apparel recycling program</span>

<span class="fontsize14">DuPont™ Tyvek® is proud to expand our long standing</span> Tyvek® Protective apparel recycling program <span class="fontsize14"> to help our customers in Europe manage used Tyvek® and IsoClean® protective apparel and reduce wastage. </span>

<span class="fontsize14">Tyvek® protective apparel recycling program</span>

<span class="fontsize14">Post-consumer recycling </span>

Tyvek® is produced using renewable electricity in its operations. This milestone was achieved by purchasing renewable energy credits (RECs).

<span class="fontsize14">Post-consumer recycling </span>

<span class="fontsize14">Recycle Your Nomex® PPE With Zero Waste Box™ System </span>

As a leading manufacturer for PPE, DuPont is excited to let its customers know that they can reach out to TerraCycle® to facilitate improved sustainability across the industry through their Fabrics and Clothing Zero Waste Box™ program.