Aerospace, marine, & rail

More Durable Aerospace, Marine, and Rail Equipment

DuPont™ Kevlar® and DuPont™ Nomex® help deliver durability, lightweight strength, stiffness, thermal and fire protection in aircraft, marine vessel and rail.

Kevlar® and Nomex® help manufacturers in aerospace, marine, and rail industries to build aircraft, ships, and rail carriages. The remarkable performance characteristics of Kevlar® and Nomex® can help to increase fuel efficiency – and decrease operating and maintenance costs.

Aircraft cabin flooring and interiors

Aircraft cabin floors, overhead bins, and bulkheads built with Nomex® or Kevlar® honeycomb cores have helped in weight savings for aircraft manufacturers. In addition to the lighter weight, honeycomb has very low electrical conductivity and high fire resistance, which helps contribute to addressing the safety standards the industry demands. The superior thermal and sound insulation also contribute to passenger comfort.

Landing gear doors

Nomex® or Kevlar® honeycombs help designers produce landing gear doors that are strong and light to allow for delivering more efficient aircraft.

Wing boxes and control surfaces

The light weight, lack of galvanic corrosion, and overall strength that Nomex® or Kevlar® honeycombs help provide for wing-to-body fairings and control surfaces make it superior to the heavier, weaker, and corrosion-susceptible aluminum core that has been used in the past.

Filament-wound pressure bottles

Bottles containing pressurized oxygen (or other gases) on airplanes use molded casings made of Kevlar® filament to help reduce the overall weight of the aircraft. An ordinary alloy-encased bottle can suffer catastrophic failure, releasing metal fragments into the aircraft at high velocity, whereas a bottle using a casing made of Kevlar® may help risk ductile failure – rupturing, rather than disintegrating – which does not result in fragmentation.

Engine nacelles

The nacelles that surround jet engines must contend with thrust, lift, and vibration forces. Manufacturers choose to use Nomex® or Kevlar® honeycomb core structures in engine nacelles because it is far stronger and lighter than earlier designs with an aluminum core.

Engine containment rings

Many jet engine manufacturers add a protective layer of Kevlar® fabric inside the engine cowl to help catch errant fan blades or massive broken parts flung outward by the engine’s centrifugal force, thus potentially preventing them from damaging the wing or the cabin.

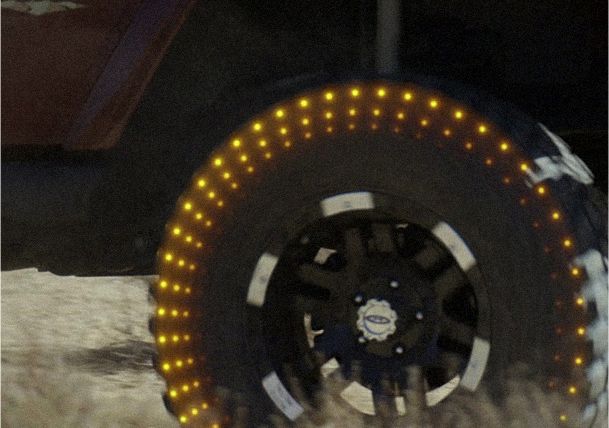

Aircraft tires

Landing and takeoff cycles, friction, and rapid changes in temperature push aircraft tires to their stress limits. Tires reinforced with Kevlar® brand aramid fiber help provide enhanced toughness and thermal stability.

Rotor blades

The alloy cores that historically predominated helicopter rotor blade designs are giving way to composites, of which honeycomb core made of Nomex® or Kevlar® is proving to be a material of choice. Modern helicopters are redefining efficiency and performance with lighter, stiffer rotor blades made of Nomex® or Kevlar®.

Spacecraft

Kevlar® fiber has proven that it is strong enough to survive the extreme forces and temperature fluctuations of space travel. When the Mars Pathfinder landed on the surface of Mars, Kevlar® fiber reinforced the inflatable landing cushions – and the ropes that secured them – helping the Pathfinder to complete its 40-million-mile journey fully intact and ready to explore the planet’s surface. Kevlar® is used in communications satellites, and also in the space shuttle, to help protect against impact from orbital debris.

Maritime vessels

Bulkheads, fixed walls, and other interior structures on U.S. Navy and Coast Guard ships use Nomex® or Kevlar® honeycombs to help save weight and mitigate the inevitable corrosion that comes from exposure to sea spray. It is also used in ferries, hydrofoil designs, and recreational boats.

Cable harness

Nomex® multifilament yarns have proven for mechanical protection and maintenance of wire and cable bundles. It provides outstanding protection against flames, high temperatures and resistance to mechanical abrasion while being soft and providing electrical insulation.

Featured

Dare Bigger™ with Kevlar® - “The Kevlar® Journey, Top To Bottom”

From 34 million miles above us to several miles below the earth’s surface and every point in-between, you’re going to see the wide and extraordinary applications of DuPont™ Kevlar®.