TK613T LY

Tychem® 10000

DuPont™ Tychem® 10000 Encapsulated Level A Suit. Certified to NFPA 1994, Class. 2. Expanded Back, Rear Entry. Extra-Wide Visor, 3 Layers: 40 mil PVC / 5 mil Teflon® / 20 mil PVC. Attached Dual Layer Gloves, Internal: Multi-layer laminate / External: Neoprene. Attached Socks with Outer Boot Flaps. Double Storm Flap with Hook & Loop Closure. Two Exhaust Valves. Double Taped Seams. Lime Yellow.

-

DOUBLE CHECK

Use Double Check to determine if this product is suitable for your hazard scenario.

- Where To Buy

Frequently Asked Questions

TK613T LY

Tychem® 10000

DUPONT™ SAFESPEC™ Terms of Use

Product Selector Agreement

The following information must be read and accepted by the user before proceeding.

The DuPont™ SafeSPEC™ Product Selector Tool (“Tool”) is intended to assist in choosing protective clothing styles for particular applications and does not replace the judgment of a qualified safety professional or industrial hygienist. Additional personal protective equipment (“PPE”), such as but not limited to: respiratory, eye, head, foot, and hand protection, may be required. Supplying the proper hazard/chemical and exposure information for your hazard scenario is critical in order to obtain suggestions of possible garment options for your consideration. Inaccurate information could result in improper suggestions. Since there are other factors involved which could affect the final PPE decision and may not be considered in this Tool, the final decision on protective clothing selection is the responsibility of the buyer, safety professional, industrial hygienist and end-user. DuPont de Nemours, Inc. or its affiliates DISCLAIM ANY RESPONSIBILITY OR LIABILITY FOR ANY INFORMATION OR SUGGESTIONS PROVIDED BY THE TOOL OR THE USE THEREOF.

WARNING / CAUTION

There are uses, environments and chemicals for which any garment will be unsuitable. It is the responsibility of the user to review available data and verify that the garment selected is appropriate for the intended use and meets all specified government and industry standards.

Search by :

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 1 of 3

You may enter from one to five chemicals or other hazards that may be present in your working environment. Our tool will find the best product match for the combined hazards. Enter a single chemical or hazard if you wish to find the best possible product match for that one hazard.

Chemical or Other Hazard Name

or

CAS Number

| Chemical Details | CAS | Actions |

|---|

Hazard Concentration information

Please read following

- You have selected a chemical that has been tested at multiple concentrations. All concentrations will be displayed on the next page so that you can review breakthrough times for each concentration.

- Please review FAQs if your hazard concentration is lower or higher than the tested concentrations

Need Help?

- If you see your CAS number in the drop down list, make sure you are selecting the hazard from the drop down list before clicking "Add to List".

- If you do not see your CAS number listed, check the number and try again or you may want to try Guide.

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 2 of 3

CHEMICAL COMPARISON

The table below shows the Normalized Breakthrough times of fabrics for the hazards selected. (Testing Details) You can find specific garments that protect against these hazards by clicking the 'Next' button below.

Done

Done

Done

|

|

|

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 3 of 3

Flammable Environments

WARNING

If any of the following apply:

- A fire or electric arc is actively present in the work environment

- The work environment contains an uncontrollable flammable material between the Lower Explosive Limit (LEL) or Lower Flammable Limit (LFL) and the Upper Explosive Limit (UEL) or Upper Flammable Limit (UFL)

- The work environment has been subject to a breach or loss in containment of flammable material (flammable liquids, flammable vapors or combustible dusts)

- There is an uncontrolled fuel source available in the work environment (that may or may not have encountered an ignition source yet)

Please consider fire fighter PPE (personal protective equipment). Read more.

If none of these conditions apply but FR clothing is required in your working environment, close this box and proceed to the next question. Only fabrics that provide both chemical resistance to the hazards you have listed and protection during escape from a flash fire will be considered for your hazard scenario.

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

step3of3

Is Suitable For Hazard Scenario

Is Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

| Hazard | Fabric/Materials | Seam | Design |

|---|

YOU MAY WANT TO CONSIDER SIMILAR PRODUCTS RELATED TO TK613T LY

Matching Products (0)

Your hazard scenario did not produce any results. May we suggest:

- If you are searching multiple hazards at one time, try breaking your search into separate hazards by either creating a new scenario or unchecking Hazards in the pane to the left. SafeSPEC™ is trying to find one garment that can be used for all of your hazards. You may need to consider more than one garment.

- If you have a liquid or vapor chemical hazard, try searching the Chemical Resistance Database. This database will show you permeation data for all of the fabrics tested against a given hazard. Once you are able to determine a suitable fabric, you will have the flexibility of selecting a suitable garment design and seam construction yourself.

- If you answered "yes" to the question that you are working in an environment that requires flame resistant clothing, please note that although DuPont has several garment options for scenarios involving possible industrial fire or electric arc exposures as well as chemical exposure hazards, these garments may not have been tested against the specific chemical hazard(s) that you have selected or may have breakthrough times lower than your intended work duration. If possible, try to mitigate the need for flame resistant clothing by implementing engineering controls, work practices and administrative controls before resorting to protective clothing. Additionally, try breaking your search into separate hazards as suggested above in order to find garment options to meet your needs.

- If you selected "localized to the feet" for the direction of exposure question, you may want to consider chemical resistant boots instead of purchasing a full garment. DuPont does not manufacture or sell chemical resistant boots. However, we do offer some coveralls and encapsulated suits with attached socks. These socks can be worn as an extra layer of protection inside of chemical resistant boots.

If you still need help, please Contact Us.

Is Suitable For Hazard Scenario

Is Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

| Hazard | Fabric/Materials | Seam | Design |

|---|

Technical Data Sheet

Related Products

DuPont™ Tychem® 10000 Encapsulated Level A Suit. Certified to NFPA 1990 (NFPA 1994, Class 2) 2022 edition. Expanded Back, Front Entry. Extra-Wide, Anti-Fog, Three-Layer Faceshield: 40 mil PVC / 5 mil Teflon™ / 20 mil PVC. Attached Dual Layer Gloves, Internal: Multi-layer laminate / External: Neoprene. Attached Socks with Outer Boot Flaps. Double Storm Flap with Hook & Loop Closure. Two Exhaust Valves. Double Taped Seams. Lime Yellow.

DuPont™ Tychem® 10000 Encapsulated Training Suit. Expanded Back, Front Entry. Extra-Wide Visor, 1 Layer: 20 mil PVC. Attached Butyl Gloves. Attached Socks with Outer Boot Flaps. Storm Flap. Taped Seams. Lime Yellow. Clearly Labeled as a Training Suit.

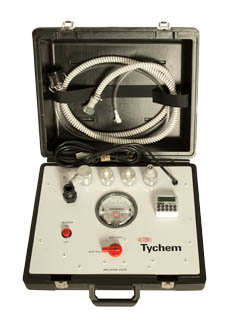

Universal Pressure Test Kit for Level A Suits. Fittings for Auer® & Pirelli® Valves.

FEATURES & PRODUCT DETAILS

Tychem® 10000 exhibits excellent chemical barrier properties and offers an extremely durable fabric that is puncture- and tear-resistant, yet supply and light weight. Tychem® 10000 fabric shows at least 30 minutes of barrier protection to 322 challenge chemicals. Tychem® 10000 is specifically developed for protection against toxic, corrosive gases, liquids and solid chemicals. This high-performance chemical barrier fabric is suited for industrial, HazMat, and domestic preparedness applications.

- Certified to NFPA 1990 (NFPA 1994, Class 2) 2022 edition

- Class 2 garments are designed for situations where there is an immediate danger to life and health (IDLH) and must be worn with a self-contained breathing apparatus (SCBA). This is the highest level of protection under the NFPA 1994 standard.

- Encapsulated Level A garment design is our highest level of protection from liquid splash and vapor/gas exposures for both the wearer and respiratory equipment

- Double taped seams provide strong chemical resistance against heavy liquid splashes. A sewn seam is covered, both inside and outside of garment with compatible chemical-resistant material by heat-sealing.

- Expanded anti-fog faceshield provides wide 220 degree viewing angle. EX faceshield is three-layer laminate composed of 40 mil PVC/5 mil Teflon™ / 20 mil PVC

- Rear entry design keeps closure away from direct contact with frontal chemical exposure and provides ability to change air bottle on SCBA without removing the entire garment

- Expanded back to accommodate self-contained air breathing apparatus (SCBA)

- Vapor tight zipper. Extra long to increase garment opening and aid donning and doffing

- Storm flap covers zipper which can be secured by the wearer with rugged hook and loop material to prevent intrusion at zipper

- Attached internal gloves composed of five layer laminate film for a broad range of chemical protection

- Neoprene gloves provide mechanical and physical durability to help protect inner gloves

- Integrated socks composed of garment material

- Attached flaps are designed to cover boot tops to help reduce potential for liquid intrusion

- Two exhaust valves release higher pressure inside encapsulating garments while simultaneously helping to prevent inward leakage of external vapors or particles into the garment. One-way valves are positive pressure and open on demand. Valves include splash covers made of barrier material to help prevent liquid intrusion. Valves are located on left back of head and right lower back. (146)

- Internal adjustable waist belt system for support and improved fit

- Each suit has a unique serial number and is fully tested at time of manufacture including positive air pressure integrity testing per ASTM F1052.

- Pass-thrus are optional and can be installed upon request when ordering. Some suits are available with optional pass-thrus to accommodate the following SCBA manufacturers: Scott, Interspiro, MSA, Draeger, Survivair®. Please call Customer Service 1-800-931-3456 for additional information. (3377)

- Made in the USA, North American Free Trade Agreement (NAFTA) compliant and Trade Agreement Act (TAA) compliant

FINISHED DIMENSIONS

| Size | Sleeve Length | Chest Width | Inseam | Fits Chest | Fits Height | Inner Glove Size | Outer Glove Size |

|---|---|---|---|---|---|---|---|

| MD | 28 | 29 1/4 | 30 | 45 1/4 - 48 3/4 | 5'0" - 5'9" | 11 | 10 |

| LG | 29 | 30 | 31 | 46 3/4 - 50 1/4 | 5'9" - 6'3" | 11 | 10 |

| XL | 29 | 30 | 31 | 46 3/4 - 50 1/4 | 5'9" - 6'3" | 11 | 10 |

| 2X | 31 | 31 1/2 | 32 1/2 | 49 3/4 - 53 1/4 | 6'3" - 6'5" | 11 | 10 |

| 3X | 31 | 31 1/2 | 32 1/2 | 49 3/4 - 53 1/4 | 6'3" - 6'5" | 11 | 10 |

| 4X | 32 1/2 | 33 | 34 1/2 | 52 3/4 - 56 1/4 | 6'5"- 6'7" | 11 | 10 |

ADDITIONAL EQUIPMENT NEEDED

- Please read, understand and follow the Tychem® User Manual.

- Please refer to the technical data package for each garment with NFPA certification for specific equipment that has been tested and certified for use with that garment.

- Suffocation hazard exists. An appropriate open-circuit self-contained breathing apparatus (SCBA) or air-line supplied respirator must be worn with all encapsulating garments.

- Wear other appropriate PPE such as, but not limited to, respiratory, eye, head, hand, and foot protection based on the hazard assessment.

- Wear separate appropriate outer footwear over the garment sock. This garment has attached socks made of garment material. These socks are not suitable to used as outer footwear. They do not have adequate durability or slip resistance to be worn as the outer foot covering. (15)

AVAILABLE OPTIONS

| Option Code | Description | Sizes | Part Number |

|---|---|---|---|

| 00 | Standard | MD,LG,XL,2X,3X,4X |

SPECIFICATIONS

- The gloves shall consist of an inner Ansell™ Barrier® glove and an outer neoprene glove.

- The garment shall be constructed of DuPont™ Tychem® 10000 -- a patented fabric consisting of multi-layer barrier films laminated to both sides of a 4.0 oz/yd2 polyester substrate.

Fabric & Permeation/Penetration Data

Physical Properties

Data relating to mechanical performance of the fabrics used in DuPont chemical protective clothing, listed for the selected garment according to the test methods and relevant European standard, if applicable. Such properties, including abrasion and flex-cracking resistance, tensile strength and puncture resistance can help in the assessment of protective performance.

- According to EN 14325

- According to EN 14126

- According to EN 1073-2

- According to EN ISO 14116

- According to EN ISO 11612

- Front Tyvek ® / Back

- Based on test according to ASTM D-572

- See Instructions for Use for further information, limitations and warnings

- Larger than

- Smaller than

- Smaller than or equal to

- Not Applicable

- Standard Deviation

PERMEATION DATA

Permeation is the process by which a solid, liquid or gaseouses chemical moves through a protective clothing fabric at a molecular level. Permeation data assist in the selection of the most appropriate protective garment for a particular application and in the estimation of how long it can be safely worn. Standardised test methods are used to determine the resistance of DuPont materials to permeation, the results of which can be selected according to a specific chemical, chemical class or fabric.

| Hazard / Chemical Name | Physical State | CAS | BT Act | BT 0.1 | BT 1.0 | EN | SSPR | MDPR | Cum 480 | Time 150 | ISO |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Acetaldehyde | Liquid | 75-07-0 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Acetic acid (>95%) | Liquid | 64-19-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Acetic acid 2 ethoxy ethyl ester | Liquid | 111-15-9 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Acetic acid 2 methoxy ethyl ester | Liquid | 110-49-6 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Acetic acid ethenyl ester | Liquid | 108-05-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Acetic acid ethyl ester | Liquid | 141-78-6 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Acetic acid pentyl ester | Liquid | 628-63-7 | >480 | >480 | >480 | 6 | <0.003 | 0.003 | <1.4 | >480 | 6 |

| Acetic anhydride | Liquid | 108-24-7 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Acetic chloride | Liquid | 75-36-5 | >480 | >480 | 6 | <0.0126 | 0.0126 | ||||

| Acetone | Liquid | 67-64-1 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Acetone cyanohydrin | Liquid | 75-86-5 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Acetonitrile | Liquid | 75-05-8 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Acetyl chloride | Liquid | 75-36-5 | >480 | >480 | 6 | <0.0126 | 0.0126 | ||||

| Acroleic acid | Liquid | 79-10-7 | >480 | >480 | >480 | 6 | <0.06 | 0.06 | <28.8 | >480 | 6 |

| Acrolein | Liquid | 107-02-8 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Acrylamide (50%) | Liquid | 79-06-1 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Acrylic acid | Liquid | 79-10-7 | >480 | >480 | >480 | 6 | <0.06 | 0.06 | <28.8 | >480 | 6 |

| Acrylic acid ethyl ester | Liquid | 140-88-5 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Acrylic acid n-butyl ester | Liquid | 141-32-2 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Acrylicamide (50%) | Liquid | 79-06-1 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Acrylonitrile | Liquid | 107-13-1 | >480 | >480 | >480 | 6 | <0.0003 | 0.0003 | |||

| Adipic acid dinitrile | Liquid | 111-69-3 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Adipic acid nitrile | Liquid | 111-69-3 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Adiponitrile | Liquid | 111-69-3 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Allyl alcohol | Liquid | 107-18-6 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Allyl chloride | Liquid | 107-05-1 | >480 | >480 | >480 | 6 | <0.06 | 0.06 | <28.8 | >480 | 6 |

| Amido sulfonic acid (15%) | Liquid | 5329-14-6 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Amino 2-methylpropane, 2- | Liquid | 75-64-9 | >480 | >480 | >480 | 6 | <0.03 | 0.03 | <14.4 | >480 | 6 |

| Amino 3,4-dichlorobenzene, 1- | Solid | 95-76-1 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Amino 3,4-dichlorobenzene, 1- (70 °C, molten) | Liquid | 95-76-1 | 128*/216 | 216*/284 | 2.4 | 0.001 | |||||

| Amino benzene | Liquid | 62-53-3 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Amino diphenyl, 4- (1 mg/ml in Methanol) | Liquid | 92-67-1 | >480 | >480 | >480 | 6 | <0.0273 | 0.0273 | <13 | >480 | 6 |

| Amino ethanol, 2- | Liquid | 141-43-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Amino ethylethanolamine | Liquid | 111-41-1 | >480 | >480 | >480 | 6 | <0.005 | 0.005 | <2.4 | >480 | 6 |

| Amino ethylethanolamine (60%) | Liquid | 111-41-1 | >480 | >480 | >480 | 6 | <0.005 | 0.005 | <2.4 | >480 | 6 |

| Amino ethylpiperazine | Liquid | 140-31-8 | >480 | >480 | >480 | 6 | <0.005 | 0.005 | <2.4 | >480 | 6 |

| Amino propane, 2- | Liquid | 75-31-0 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Ammonia (-33 °C, liquid) | Liquid | 7664-41-7 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <0.59 | >480 | 6 |

| Ammonia (-70 °C, liquid) | Liquid | 7664-41-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Ammonia (gaseous) | Vapor | 7664-41-7 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Ammonium fluoride (40%) | Liquid | 12125-01-8 | >480 | >480 | 6 | <0.1 | 0.01 | ||||

| Ammonium hydroxide (28% - 30%) | Liquid | 1336-21-6 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Amyl acetate, n- | Liquid | 628-63-7 | >480 | >480 | >480 | 6 | <0.003 | 0.003 | <1.4 | >480 | 6 |

| Amyl ester acetic acid | Liquid | 628-63-7 | >480 | >480 | >480 | 6 | <0.003 | 0.003 | <1.4 | >480 | 6 |

| Aniline | Liquid | 62-53-3 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Arsine | Vapor | 7784-42-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Aziridine | Liquid | 151-56-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Azolidine | Liquid | 123-75-1 | 407 | 413 | 9.2 | 0.012 | |||||

| Benzenamine | Liquid | 62-53-3 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Benzene | Liquid | 71-43-2 | >480 | >480 | >480 | 6 | <0.0008 | 0.0008 | <0.48 | >480 | 6 |

| Benzene carbonyl chloride | Liquid | 98-88-4 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Benzene sulfone chloride | Liquid | 98-09-9 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Benzene sulfonyl chloride | Liquid | 98-09-9 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Benzene thiol | Liquid | 108-98-5 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Benzidine (25% in Methanol) | Liquid | 92-87-5 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Benzidine (75% in Methanol) | Liquid | 92-87-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Benzo nitrile | Liquid | 100-47-0 | >480 | >480 | >480 | 6 | <0.004 | 0.004 | <1.9 | >480 | 6 |

| Benzoyl chloride | Liquid | 98-88-4 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Benzyl chloride | Liquid | 100-44-7 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Biphenyl 4,4'-diamine, 1,1'- (25% in Methanol) | Liquid | 92-87-5 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Biphenyl 4,4'-diamine, 1,1'- (75% in Methanol) | Liquid | 92-87-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Bis (4-(2,3-epoxypropoxy)phenyl)propane | Liquid | 1675-54-3 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Bis phenol A diglycidyl ether | Liquid | 1675-54-3 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Black Liquor (mix) | Liquid | mix | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Boron fluoride ethyl ether | Liquid | 109-63-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Boron trichloride | Vapor | 10294-34-5 | >480 | >480 | 6 | <0.1 | 0.00118 | ||||

| Boron trifluoride | Vapor | 7637-07-2 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Boron trifluoride diethyl etherate | Liquid | 109-63-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Boron trifluoride etherate | Liquid | 109-63-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Brom wasserstoff (gasförmig) | Vapor | 10035-10-6 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Bromine | Liquid | 7726-95-6 | 15 | 15 | 15 | 1 | 25 | 0.01 | |||

| Bromine (10 g/m2) | Liquid | 7726-95-6 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Bromine (sat vapour) | Vapor | 7726-95-6 | 30*/40 | 30*/40 | 30*/40 | 1 | >0.59 | 0.1 | |||

| Bromo 4-fluorobenzene, 1- | Liquid | 460-00-4 | >480 | >480 | >480 | 6 | <0.0013 | 0.0013 | <0.6 | >480 | 6 |

| Bromo fluorobenzene, 4- | Liquid | 460-00-4 | >480 | >480 | >480 | 6 | <0.0013 | 0.0013 | <0.6 | >480 | 6 |

| Bromo methane | Vapor | 74-83-9 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Butadiene, 1,3- (0 °C, liquid) | Liquid | 106-99-0 | >180 | >180 | >180 | 4 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Butadiene, 1,3- (gaseous) | Vapor | 106-99-0 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Butanal, n- | Liquid | 123-72-8 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Butanol, 1- | Liquid | 71-36-3 | >480 | >480 | >480 | 6 | <0.002 | 0.002 | <1 | >480 | 6 |

| Butanol, n- | Liquid | 71-36-3 | >480 | >480 | >480 | 6 | <0.002 | 0.002 | <1 | >480 | 6 |

| Butanone | Liquid | 78-93-3 | >480 | >480 | >480 | 6 | <0.0067 | 0.0067 | <3.2 | >480 | 6 |

| Butanone oxime, 2- | Liquid | 96-29-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Butenal, 2- | Liquid | 123-73-9 | >480 | >480 | 6 | <0.1 | 0.006 | ||||

| Butyl acetate, n- | Liquid | 123-86-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Butyl acrylate, n- | Liquid | 141-32-2 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Butyl alcohol, n- | Liquid | 71-36-3 | >480 | >480 | >480 | 6 | <0.002 | 0.002 | <1 | >480 | 6 |

| Butyl amine | Liquid | 109-73-9 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Butyl amine, tert- | Liquid | 75-64-9 | >480 | >480 | >480 | 6 | <0.03 | 0.03 | <14.4 | >480 | 6 |

| Butyl ether, n- | Liquid | 142-96-1 | 228*/396 | >480 | >480 | 6 | 0.001 | 0.001 | |||

| Butyraldehyde, n- | Liquid | 123-72-8 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Carbon disulfide | Liquid | 75-15-0 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Carbon monoxide | Vapor | 630-08-0 | 330 | 330 | >480 | 6 | 0.1 | 0.1 | |||

| Carbon tetrachloride | Liquid | 56-23-5 | >480 | >480 | >480 | 6 | <0.015 | 0.015 | <7.2 | >480 | 6 |

| Carbon tetrafluoride | Vapor | 75-73-0 | >480 | >480 | >480 | 6 | <0.0177 | 0.0177 | <8.5 | >480 | 6 |

| Caustic ammonia (28% - 30%) | Liquid | 1336-21-6 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Caustic soda (50%) | Liquid | 1310-73-2 | >480 | >480 | >480 | 6 | <0.03 | 0.03 | <14.4 | >480 | 6 |

| Cellosolve acetate | Liquid | 110-80-5 | >480 | >480 | >480 | 6 | <0.008 | 0.008 | <3.8 | >480 | 6 |

| Chlor allylene | Liquid | 107-05-1 | >480 | >480 | >480 | 6 | <0.06 | 0.06 | <28.8 | >480 | 6 |

| Chlordane (60-75%) | Liquid | 57-74-9 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Chlorine (-70 °C, liquid) | Liquid | 7782-50-5 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Chlorine (gaseous) | Vapor | 7782-50-5 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Chlorine sulfide | Liquid | 10545-99-0 | 440 | 440 | >480 | 6 | <0.3 | 0.1 | <48 | >480 | 6 |

| Chlorine sulfide (80%) | Liquid | 10545-99-0 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Chlorine trifluoride | Vapor | 7790-91-2 | 45 | 45 | 45 | 2 | 96 | 0.1 | |||

| Chloro 1,2-propanediol, 3- | Liquid | 96-24-2 | >480 | >480 | 6 | <0.0142 | 0.0142 | ||||

| Chloro 1-methylbenzene, 2- | Liquid | 95-49-8 | >480 | >480 | >480 | 6 | <0.0001 | 0.0001 | <0.04 | >480 | 6 |

| Chloro 2,3-epoxy propane, 1- | Liquid | 106-89-8 | >480 | >480 | >480 | 6 | <0.014 | 0.014 | <6.7 | >480 | 6 |

| Chloro acetic acid (80%) | Liquid | 79-11-8 | >480 | >480 | 6 | <0.01 | 0.01 | ||||

| Chloro acetyl chloride | Liquid | 79-04-9 | 160 | 160 | 170 | 4 | 23.2 | 0.1 | |||

| Chloro aniline, p- | Solid | 106-47-8 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Chloro aniline, p- (70 °C, molten) | Liquid | 106-47-8 | 272 | 272*/323 | 355 | 5 | 9.4 | 0.001 | |||

| Chloro benzenamine, 4- | Solid | 106-47-8 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Chloro benzenamine, 4- (70 °C, molten) | Liquid | 106-47-8 | 272 | 272*/323 | 355 | 5 | 9.4 | 0.001 | |||

| Chloro benzene | Liquid | 108-90-7 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Chloro ethanol, 2- | Liquid | 107-07-3 | >480 | >480 | >480 | 6 | <0.0082 | 0.0082 | <3.9 | >480 | 6 |

| Chloro ethene | Vapor | 75-01-4 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Chloro methyl methyl ether | Liquid | 107-30-2 | 305 | >480 | >480 | 6 | 0.03 | 0.001 | |||

| Chloro phenol, p- (sat in Methanol) | Liquid | 106-48-9 | >480 | >480 | >480 | 6 | <0.013 | 0.013 | <6.2 | >480 | 6 |

| Chloro prene, 3- | Liquid | 107-05-1 | >480 | >480 | >480 | 6 | <0.06 | 0.06 | <28.8 | >480 | 6 |

| Chloro toluene, alpha- | Liquid | 100-44-7 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Chloro toluene, o- | Liquid | 95-49-8 | >480 | >480 | >480 | 6 | <0.0001 | 0.0001 | <0.04 | >480 | 6 |

| Chloroform | Liquid | 67-66-3 | >480 | >480 | >480 | 6 | <0.0037 | 0.0037 | <1.7 | >480 | 6 |

| Chlorsulfonic acid | Liquid | 7790-94-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Chromic acid (CrO3) (44.9%) | Liquid | 1333-82-0 | >480 | >480 | >480 | 6 | <0.07 | 0.07 | <33.6 | >480 | 6 |

| Cresols, mixed isomers | Liquid | 1319-77-3 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Cresylic acid | Liquid | 1319-77-3 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Croton aldehyde | Liquid | 123-73-9 | >480 | >480 | 6 | <0.1 | 0.006 | ||||

| Crude oil, California | Liquid | 8002-05-9 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Cumene | Liquid | 98-82-8 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Cyanide chloride (20% in Toluene) | Liquid | 108-77-0 | >480 | >480 | >480 | 6 | <0.10 | 0.1 | <48 | >480 | 6 |

| Cyanobenzene | Liquid | 100-47-0 | >480 | >480 | >480 | 6 | <0.004 | 0.004 | <1.9 | >480 | 6 |

| Cyanoethylene | Liquid | 107-13-1 | >480 | >480 | >480 | 6 | <0.0003 | 0.0003 | |||

| Cyanomethane | Liquid | 75-05-8 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Cyanopropan-2-ol, 2- | Liquid | 75-86-5 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Cyanwasserstoff (21 °C, flüssig) | Liquid | 74-90-8 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Cyanwasserstoff (27 °C, gasförmig) | Vapor | 74-90-8 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Cyclo hexane | Liquid | 110-82-7 | >480 | >480 | >480 | 6 | <0.0028 | 0.0028 | <1.3 | >480 | 6 |

| Cyclo hexanone | Liquid | 108-94-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Diaminobiphenyl, 4,4'- (25% in Methanol) | Liquid | 92-87-5 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Diaminobiphenyl, 4,4'- (75% in Methanol) | Liquid | 92-87-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Diaminodiphenyl, p- (25% in Methanol) | Liquid | 92-87-5 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Diaminodiphenyl, p- (75% in Methanol) | Liquid | 92-87-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Diaminodiphenylmethane, 4,4'- | Liquid | 101-77-9 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <4.8 | >480 | 6 |

| Diaminodiphenylmethane, 4,4'- (15% in Methyl Ethyl Ketone) | Liquid | 101-77-9 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Diaminoethane, 1,2- | Liquid | 107-15-3 | >480 | >480 | >480 | 6 | <0.0097 | 0.0097 | <4.7 | >480 | 6 |

| Diborane (10%) | Vapor | 19287-45-7 | >480 | >480 | 6 | <0.1 | 0.0045 | ||||

| Dibromoethane, 1,2- | Liquid | 106-93-4 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Dichlorbenzen, 1,2- | Liquid | 95-50-1 | >480 | >480 | >480 | 6 | <0.005 | 0.005 | <2.4 | >480 | 6 |

| Dichlorbenzen, 1,3- | Liquid | 541-73-1 | >480 | >480 | >480 | 6 | <0.005 | 0.005 | <2.4 | >480 | 6 |

| Dichlorbenzen, 1,4- (50% in Ethanol) | Liquid | 106-46-7 | 251 | >480 | >480 | 6 | <0.02 | 0.005 | <0.9 | >480 | 6 |

| Dichlorethane, 1.2.- | Liquid | 107-06-2 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Dichloro -2-propanone, 1,3- (95% at 40 °C, molten) | Liquid | 534-07-6 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Dichloro -4,4'-methylenedianiline, 2,2'- (sat in Methanol) | Liquid | 101-14-4 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Dichloro -6-isopropyl-S-triazine, 2,4- (22% in Toluene) | Liquid | 30894-74-7 | >480 | >480 | >480 | 6 | <0.10 | 0.1 | <48 | >480 | 6 |

| Dichloro acetone, 1,3- (95% at 40 °C, molten) | Liquid | 534-07-6 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Dichloro acetyl chloride | Liquid | 79-36-7 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Dichloro aniline, 3,4- | Solid | 95-76-1 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Dichloro aniline, 3,4- (70 °C, molten) | Liquid | 95-76-1 | 128*/216 | 216*/284 | 2.4 | 0.001 | |||||

| Dichloro ethyl ether | Liquid | 111-44-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Dichloro ethylene, 1,1- | Liquid | 75-35-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Dichloro methane | Liquid | 75-09-2 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Dichloro propene, 2,3- | Liquid | 78-88-6 | >480 | >480 | >480 | 6 | <0.0081 | 0.0081 | <3.8 | >480 | 6 |

| Dichloro silane | Vapor | 4109-96-0 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Dicyanobutane, 1,4- | Liquid | 111-69-3 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Diesel Fuel Grade D-2 | Liquid | mix | >480 | >480 | >480 | 6 | <0.03 | 0.03 | <14.4 | >480 | 6 |

| Diesel fuel | Liquid | 68334-30-5 | >480 | >480 | >480 | 6 | <0.03 | 0.03 | <14.4 | >480 | 6 |

| Diethyl amine | Liquid | 109-89-7 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Diethyl aniline, N,N- | Liquid | 91-66-7 | >480 | >480 | >480 | 6 | <0.024 | 0.024 | <11.5 | >480 | 6 |

| Diethyl benzene (95%) | Liquid | 25340-17-4 | >480 | >480 | >480 | 6 | <0.022 | 0.022 | <10.6 | >480 | 6 |

| Diethyl ethanamine, N,N- | Liquid | 121-44-8 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Diethyl ether | Liquid | 60-29-7 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Diethyl hexyl phthalate | Liquid | 117-81-7 | >480 | >480 | >480 | 6 | <0.07 | 0.07 | <33.6 | >480 | 6 |

| Diethyl sulfate | Liquid | 64-67-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Diethylene imide oxide | Liquid | 110-91-8 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Diethylene triamine | Liquid | 111-40-0 | >480 | >480 | >480 | 6 | <0.0166 | 0.0166 | <8 | >480 | 6 |

| Diiodo-1,1,2,2-tetrafluorobutane, 1,4- | Liquid | 755-95-3 | >480 | ||||||||

| Dimethyl acetamide, N,N- | Liquid | 127-19-5 | >480 | >480 | >480 | 6 | <0.006 | 0.006 | <2.9 | >480 | 6 |

| Dimethyl amine | Vapor | 124-40-3 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Dimethyl aniline, N,N- | Liquid | 121-69-7 | >480 | >480 | >480 | 6 | <0.013 | 0.013 | <6.2 | >480 | 6 |

| Dimethyl dichlorosilane | Liquid | 75-78-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Dimethyl ether | Vapor | 115-10-6 | >480 | >480 | >480 | 6 | <0.07 | 0.07 | <33.6 | >480 | 6 |

| Dimethyl formamide, N,N- | Liquid | 68-12-2 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Dimethyl hydrazine, N,N- | Liquid | 57-14-7 | >4808 | ||||||||

| Dimethyl ketal | Liquid | 67-64-1 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Dimethyl ketone | Liquid | 67-64-1 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Dimethyl phenylamine, N,N- | Liquid | 121-69-7 | >480 | >480 | >480 | 6 | <0.013 | 0.013 | <6.2 | >480 | 6 |

| Dimethyl sulfate | Liquid | 77-78-1 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Dimethyl sulfoxide | Liquid | 67-68-5 | 164*/372 | >480 | >480 | 6 | 0.003 | 0.001 | <14.4 | >480 | 6 |

| Dinitro-o-cresol, 4,6- (sat in Methanol) | Liquid | 534-52-1 | >480 | >480 | >480 | 6 | <0.013 | 0.013 | <6.2 | >480 | 6 |

| Dinitrocresol (sat in Methanol) | Liquid | 534-52-1 | >480 | >480 | >480 | 6 | <0.013 | 0.013 | <6.2 | >480 | 6 |

| Dioxane, 1,4- | Liquid | 123-91-1 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Diphenyl methane diisocyanate, 4,4'- | Solid | 101-68-8 | >480 | >480 | >480 | 6 | <0.07 | 0.07 | <33.6 | >480 | 6 |

| Diphenyl methane diisocyanate, 4,4'- (50 °C, molten) | Liquid | 101-68-8 | >480 | >480 | >480 | 6 | <0.0403 | 0.0403 | <19.3 | >480 | 6 |

| Disodium sulfide (60% (slurry)) | Liquid | 1313-82-2 | >480 | >480 | 6 | <0.1 | 0.052 | ||||

| Disulphur dichloride | Liquid | 10025-67-9 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Epichlorohydrin | Liquid | 106-89-8 | >480 | >480 | >480 | 6 | <0.014 | 0.014 | <6.7 | >480 | 6 |

| Epoxy ethane (-70 °C, liquid) | Liquid | 75-21-8 | >180 | >180 | >180 | 4 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Epoxy ethane (0 °C, liquid) | Liquid | 75-21-8 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Epoxy ethane (10% in HCFC) | Vapor | 75-21-8 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Epoxy ethane (gaseous) | Vapor | 75-21-8 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Epoxy propane, 1,2- | Liquid | 75-56-9 | >480 | >480 | >480 | 6 | <0.0016 | 0.0016 | <0.7 | >480 | 6 |

| Ethane 1,2-diol | Liquid | 107-21-1 | >480 | >480 | 6 | <0.1 | 0.014 | ||||

| Ethane dioic acid (10.5%) | Liquid | 144-62-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Ethane diol dipropanoate, 1,2- | Liquid | 123-73-9 | >480 | >480 | 6 | <0.1 | 0.006 | ||||

| Ethane nitrile | Liquid | 75-05-8 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Ethane thiol | Liquid | 75-08-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Ethane trichloride | Liquid | 79-00-5 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Ethanol amine | Liquid | 141-43-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Ethanoyl chloride | Liquid | 75-36-5 | >480 | >480 | 6 | <0.0126 | 0.0126 | ||||

| Ethanoyl chloride | Vapor | 75-00-3 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Ethoxy ethanol, 2- | Liquid | 110-80-5 | >480 | >480 | >480 | 6 | <0.008 | 0.008 | <3.8 | >480 | 6 |

| Ethoxy ethylacetat | Liquid | 111-15-9 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Ethyl Cellosolve® | Liquid | 110-80-5 | >480 | >480 | >480 | 6 | <0.008 | 0.008 | <3.8 | >480 | 6 |

| Ethyl acetate | Liquid | 141-78-6 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Ethyl acrylate | Liquid | 140-88-5 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Ethyl amine (15 °C, liquid) | Liquid | 75-04-7 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Ethyl benzene | Liquid | 100-41-4 | >480 | >480 | >480 | 6 | <0.005 | 0.005 | <2.4 | >480 | 6 |

| Ethyl chloride | Vapor | 75-00-3 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Ethyl ethanamine, N- | Liquid | 109-89-7 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Ethyl ether | Liquid | 60-29-7 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Ethyl glycol acetate | Liquid | 111-15-9 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Ethyl mercaptan | Liquid | 75-08-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Ethyl nitrile | Liquid | 75-05-8 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Ethyl parathion | Liquid | 56-38-2 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Ethylene carboxylic acid | Liquid | 79-10-7 | >480 | >480 | >480 | 6 | <0.06 | 0.06 | <28.8 | >480 | 6 |

| Ethylene chlorohydrin | Liquid | 107-07-3 | >480 | >480 | >480 | 6 | <0.0082 | 0.0082 | <3.9 | >480 | 6 |

| Ethylene diamine | Liquid | 107-15-3 | >480 | >480 | >480 | 6 | <0.0097 | 0.0097 | <4.7 | >480 | 6 |

| Ethylene dibromide | Liquid | 106-93-4 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Ethylene dichloride | Liquid | 107-06-2 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Ethylene glycol | Liquid | 107-21-1 | >480 | >480 | 6 | <0.1 | 0.014 | ||||

| Ethylene glycol mono ethyl ether acetate | Liquid | 111-15-9 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Ethylene glycol monoethyl ether | Liquid | 110-80-5 | >480 | >480 | >480 | 6 | <0.008 | 0.008 | <3.8 | >480 | 6 |

| Ethylene glycol monomethyl ether | Liquid | 109-86-4 | >480 | >480 | >480 | 6 | <0.005 | 0.005 | <4.8 | >480 | 6 |

| Ethylene glycol monomethyl ether acetate | Liquid | 110-49-6 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Ethylene imine | Liquid | 151-56-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Ethylene oxide (-70 °C, liquid) | Liquid | 75-21-8 | >180 | >180 | >180 | 4 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Ethylene oxide (0 °C, liquid) | Liquid | 75-21-8 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Ethylene oxide (10% in HCFC) | Vapor | 75-21-8 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Ethylene oxide (gaseous) | Vapor | 75-21-8 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Ethylene tetrachloride | Liquid | 127-18-4 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Ethylene trichloride | Liquid | 79-01-6 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Fluorine | Vapor | 7782-41-4 | >480 | >480 | >480 | 6 | <0.002 | 0.002 | <1 | >480 | 6 |

| Fluorobenzene | Liquid | 462-06-6 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Fluoroform | Vapor | 75-46-7 | >480 | >480 | 6 | <0.0141 | 0.0141 | ||||

| Fluorosulfonic acid | Liquid | 7789-21-1 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Formaldehyde (100 ppm) | Vapor | 50-00-0 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Formalin (100 ppm) | Vapor | 50-00-0 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Formalin (37% (10-15% Methanol)) | Liquid | 50-00-0 | >480 | >480 | >480 | 6 | <0.0048 | 0.0048 | <2.3 | >480 | 6 |

| Formic acid (>95%) | Liquid | 64-18-6 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Furaldehyde, 2- | Liquid | 98-01-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Furfural | Liquid | 98-01-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Gasoline, leaded | Liquid | mix | >480 | >480 | >480 | 6 | <0.56 ppm | 0.056 ppm | |||

| Gasoline, unleaded | Liquid | 86290-81-5 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Glutaral (5%) | Liquid | 111-30-8 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Glutaral (50%) | Liquid | 111-30-8 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Glutaraldehyde (5%) | Liquid | 111-30-8 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Glutaraldehyde (50%) | Liquid | 111-30-8 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Glycol alcohol | Liquid | 107-21-1 | >480 | >480 | 6 | <0.1 | 0.014 | ||||

| Glycol chlorohydrin | Liquid | 107-07-3 | >480 | >480 | >480 | 6 | <0.0082 | 0.0082 | <3.9 | >480 | 6 |

| Glycolic acid (sat) | Liquid | 79-14-1 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Green Liquor (mix) | Liquid | mix | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Hexachloro butadiene | Liquid | 87-68-3 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Hexachloro cyclohexane, 1,2,3,4,5,6- (sat in Acetone) | Liquid | 58-89-9 | >480 | >480 | >480 | 6 | <0.06 | 0.06 | <28.8 | >480 | 6 |

| Hexachloro cyclohexane, 1,2,3,4,5,6- (sat in Methanol) | Liquid | 58-89-9 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Hexafluoro ethane | Vapor | 76-16-4 | >480 | >480 | 6 | <0.1 | 0.0139 | ||||

| Hexafluoro isobutylene | Vapor | 382-10-5 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Hexamethyl disilazane | Liquid | 999-97-3 | >480 | >480 | 6 | <0.1 | 0.014 | ||||

| Hexamethyl disilazane, 1,1,1,3,3,3- | Liquid | 999-97-3 | >480 | >480 | 6 | <0.1 | 0.014 | ||||

| Hexamethylene diamine (45 °C, molten) | Liquid | 124-09-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Hexamethylene diisocyanate | Liquid | 822-06-0 | >480 | >480 | >480 | 6 | <0.0271 | 0.0271 | <13 | >480 | 6 |

| Hexane, n- | Liquid | 110-54-3 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Hexanone | Liquid | 108-94-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Hexone | Liquid | 108-10-1 | 32*/120 | >480 | >480 | 6 | <0.1 | 0.001 | |||

| Hydrazine | Liquid | 302-01-2 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Hydrazine hydrate (51%) | Liquid | 10217-52-4 | >480 | >480 | >480 | 6 | <0.06 | 0.06 | <28.8 | >480 | 6 |

| Hydrazine hydrate (85%) | Liquid | 10217-52-4 | 240*/360 | 440 | >480 | 6 | 0.06 | 0.004 | |||

| Hydriodic acid (55-57%) | Liquid | 10034-85-2 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Hydrochloric acid (37%) | Liquid | 7647-01-0 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Hydrofluoric acid (48-51%) | Liquid | 7664-39-3 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Hydrofluoric acid (70%) | Liquid | 7664-39-3 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Hydrogen bromide (gaseous) | Vapor | 10035-10-6 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Hydrogen chloride (-90 °C, liquid) | Liquid | 7647-01-0 | >180 | >180 | >180 | 4 | <0.1 | 0.1 | <48 | >480 | 6 |

| Hydrogen chloride (gaseous) | Vapor | 7647-01-0 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Hydrogen cyanide (21 °C, liquid) | Liquid | 74-90-8 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Hydrogen cyanide (27 °C, gaseous) | Vapor | 74-90-8 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Hydrogen fluoride (20-27 °C, gaseous) | Vapor | 7664-39-3 | >480 | >480 | >480 | 6 | <0.025 | 0.025 | <12 | >480 | 6 |

| Hydrogen peroxide (30%) | Liquid | 7722-84-1 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Hydrogen peroxide (70%) | Liquid | 7722-84-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Hydrogen selenide | Vapor | 7783-07-5 | >480 | ||||||||

| Hydrogen sulfide | Vapor | 7783-06-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Hydroxy 1-ethanethiol, 2- | Liquid | 60-24-2 | >480 | >480 | >480 | 6 | <0.08 | 0.08 | <38.4 | >480 | 6 |

| Hydroxy 2-methylpropionitrile, 2- | Liquid | 75-86-5 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Hydroxy 2-nitrobenzene, 1- (70 °C, molten) | Liquid | 88-75-5 | 208 | >480 | 6 | 0.17 | 0.004 | ||||

| Hydroxy acetic acid (sat) | Liquid | 79-14-1 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Hydroxy chlorobenzene (sat in Methanol) | Liquid | 106-48-9 | >480 | >480 | >480 | 6 | <0.013 | 0.013 | <6.2 | >480 | 6 |

| Hydroxy isobutyronitrile | Liquid | 75-86-5 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Iodomethane | Liquid | 74-88-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Isobutyl methyl ketone | Liquid | 108-10-1 | 32*/120 | >480 | >480 | 6 | <0.1 | 0.001 | |||

| Isopropanol | Liquid | 67-63-0 | >480 | >480 | >480 | 6 | <0.0097 | 0.0097 | <4.7 | >480 | 6 |

| Isopropyl alcohol | Liquid | 67-63-0 | >480 | >480 | >480 | 6 | <0.0097 | 0.0097 | <4.7 | >480 | 6 |

| Isopropyl amine | Liquid | 75-31-0 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Isopropyl benzene | Liquid | 98-82-8 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Isopropylidenediphenol diglycidyl ether, 4,4'- | Liquid | 1675-54-3 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| JP-4 Jet Fuel | Liquid | 50815-00-4 | >480 | >480 | >480 | 6 | <0.0017 | 0.0017 | |||

| JP-8 Jet Fuel | Liquid | 94114-58-6 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Ketone propane | Liquid | 67-64-1 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Lewisite (L), MIL-STD-282 (10 g/m2) | Liquid | 541-25-3 | >4808 | ||||||||

| Lewisite (L), MIL-STD-282 (100 g/m2) | Liquid | 541-25-3 | >4808 | ||||||||

| Limonene d- | Liquid | 5989-27-5 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Lindane (sat in Acetone) | Liquid | 58-89-9 | >480 | >480 | >480 | 6 | <0.06 | 0.06 | <28.8 | >480 | 6 |

| Lindane (sat in Methanol) | Liquid | 58-89-9 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Low boiling point naphtha - unspecified | Liquid | 8052-41-3 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Malathion | Liquid | 121-75-5 | >480 | >480 | >480 | 6 | <0.013 | 0.013 | <6.2 | >480 | 6 |

| Mercapto acetic acid | Liquid | 68-11-1 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Mercapto ethanol | Liquid | 60-24-2 | >480 | >480 | >480 | 6 | <0.08 | 0.08 | <38.4 | >480 | 6 |

| Mercuric II chloride (sat) | Liquid | 7487-94-7 | >4808 | ||||||||

| Mercury | Liquid | 7439-97-6 | >480 | >480 | >480 | 6 | <0.09 | 0.09 | <43.2 | >480 | 6 |

| Methacrylic acid | Liquid | 79-41-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Methanesulfonyl chloride | Liquid | 124-63-0 | >480 | >480 | 6 | <0.1 | 0.0006 | ||||

| Methanethiol | Vapor | 74-93-1 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Methanol | Liquid | 67-56-1 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Methomyl (29%) | Liquid | 16752-77-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Methoxy 2-methylpropane, 2- | Liquid | 1634-04-4 | >480 | >480 | >480 | 6 | <0.007 | 0.007 | |||

| Methoxy chloromethane | Liquid | 107-30-2 | 305 | >480 | >480 | 6 | 0.03 | 0.001 | |||

| Methoxy ethanol, 2 | Liquid | 109-86-4 | >480 | >480 | >480 | 6 | <0.005 | 0.005 | <4.8 | >480 | 6 |

| Methoxy ethylacetate, 2- | Liquid | 110-49-6 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Methyl 1,5-pentantedinitrile, 2- (87%) | Liquid | 4553-62-2 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Methyl 2-methyl-2-propenoate | Liquid | 80-62-6 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Methyl 2-pyrrolidone, N- | Liquid | 872-50-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Methyl 4-isopropenyl-1-cyclohexene, 1- | Liquid | 5989-27-5 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Methyl acetyl | Liquid | 67-64-1 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Methyl acrolein | Liquid | 123-73-9 | >480 | >480 | 6 | <0.1 | 0.006 | ||||

| Methyl acrylate | Liquid | 96-33-3 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Methyl amine (40%) | Liquid | 74-89-5 | 72 | 261 | 3.9 | 0.017 | |||||

| Methyl amine (50%) | Liquid | 74-89-5 | 204 | 232 | |||||||

| Methyl amine (gaseous) | Vapor | 74-89-5 | >480 | >480 | >480 | 6 | <0.06 | 0.06 | <28.8 | >480 | 6 |

| Methyl aniline, o- | Liquid | 95-53-4 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Methyl benzol | Liquid | 108-88-3 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Methyl bromide | Vapor | 74-83-9 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Methyl chloride (-70 °C, liquid) | Vapor | 74-83-9 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Methyl chloride (-70 °C, liquid) | Liquid | 74-87-3 | >180 | >180 | >180 | 4 | <0.05 | 0.05 | <24 | >480 | 6 |

| Methyl chloride (gaseous) | Vapor | 74-87-3 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Methyl chloro formate | Liquid | 79-22-1 | >480 | >480 | 6 | <0.1 | 0.011 | ||||

| Methyl chloroform | Liquid | 71-55-6 | >480 | >480 | >480 | 6 | <0.004 | 0.004 | <1.9 | >480 | 6 |

| Methyl cyanide | Liquid | 75-05-8 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Methyl ethyl ketone | Liquid | 78-93-3 | >480 | >480 | >480 | 6 | <0.0067 | 0.0067 | <3.2 | >480 | 6 |

| Methyl ethyl ketoxime | Liquid | 96-29-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Methyl fluoride | Vapor | 593-53-3 | >480 | >480 | 6 | <0.1 | 0.0205 | ||||

| Methyl hydrazine | Liquid | 60-34-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Methyl iodide | Liquid | 74-88-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Methyl isocyanate | Liquid | 624-83-9 | >480 | >480 | >480 | 6 | <0.013 | 0.013 | <6.2 | >480 | 6 |

| Methyl ketone | Liquid | 67-64-1 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Methyl mercaptan | Vapor | 74-93-1 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Methyl methacrylate | Liquid | 80-62-6 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Methyl pentan-2-one, 4- | Liquid | 108-10-1 | 32*/120 | >480 | >480 | 6 | <0.1 | 0.001 | |||

| Methyl phenols | Liquid | 1319-77-3 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Methyl propenoic acid, 2- | Liquid | 79-41-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Methyl pyridine, 2- | Liquid | 109-06-8 | >480 | >480 | >480 | 6 | <0.024 | 0.024 | <11.5 | >480 | 6 |

| Methyl pyridine, 3- | Liquid | 108-99-6 | >480 | >480 | >480 | 6 | <0.024 | 0.024 | <11.5 | >480 | 6 |

| Methyl tert-butyl ether | Liquid | 1634-04-4 | >480 | >480 | >480 | 6 | <0.007 | 0.007 | |||

| Methyl trichloromethane | Liquid | 71-55-6 | >480 | >480 | >480 | 6 | <0.004 | 0.004 | <1.9 | >480 | 6 |

| Methyl trichlorosilane | Liquid | 75-79-6 | >480 | >480 | >480 | 6 | <0.007 | 0.007 | <3.4 | >480 | 6 |

| Methylene bis(2-Chloroaniline), 4,4- (sat in Methanol) | Liquid | 101-14-4 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Methylene chloride | Liquid | 75-09-2 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Methylene dianiline | Liquid | 101-77-9 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <4.8 | >480 | 6 |

| Methylene dianiline (15% in Methyl Ethyl Ketone) | Liquid | 101-77-9 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Methylene diphenyl diisocyanate, 4,4'- | Solid | 101-68-8 | >480 | >480 | >480 | 6 | <0.07 | 0.07 | <33.6 | >480 | 6 |

| Methylene diphenyl diisocyanate, 4,4'- (50 °C, molten) | Liquid | 101-68-8 | >480 | >480 | >480 | 6 | <0.0403 | 0.0403 | <19.3 | >480 | 6 |

| Mineral spirit | Liquid | 64475-85-0 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Morpholine | Liquid | 110-91-8 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Méthyl aziridine, 2- (90%) | Liquid | 75-55-8 | 120 | 150 | >480 | 6 | 0.34 | 0.01 | |||

| Naphthalene (25% in Diethylene glycol dimethylether) | Liquid | 91-20-3 | >480 | >480 | >480 | 6 | <0.007 | 0.007 | <3.4 | >480 | 6 |

| Nickel carbonyl | Liquid | 13463-39-3 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Nicotine | Liquid | 54-11-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Nitric acid (70%) | Liquid | 7697-37-2 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Nitric acid (90%) | Liquid | 7697-37-2 | >480 | >480 | 6 | <0.1 | 0.033 | ||||

| Nitric acid (>95%) | Liquid | 7697-37-2 | 390 | 390 | 420 | 5 | 3.6 | 0.1 | |||

| Nitric acid, red fuming (90%) | Liquid | 52583-42-3 | >480 | >480 | 6 | <0.1 | 0.033 | ||||

| Nitric oxide | Vapor | 10102-43-9 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Nitro benzene | Liquid | 98-95-3 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Nitro methane | Liquid | 75-52-5 | >480 | >480 | >480 | 6 | <0.005 | 0.005 | <2.4 | >480 | 6 |

| Nitro phenol, o- (70 °C, molten) | Liquid | 88-75-5 | 208 | >480 | 6 | 0.17 | 0.004 | ||||

| Nitro propane, 2- | Liquid | 79-46-9 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Nitrogen tetroxide | Liquid | 10544-72-6 | 60 | >480 | >480 | 6 | |||||

| Nitrogen tetroxide (21 °C, liquid) | Liquid | 10544-72-6 | 450 | 450 | >480 | 6 | 0.2 | 0.1 | |||

| Nitrogen tetroxide (gaseous) | Vapor | 10544-72-6 | 90 | 90 | >1.1 | 0.003 | |||||

| Nitrogen trifluoride | Vapor | 7783-54-2 | >480 | >480 | 6 | <0.014 | 0.014 | ||||

| Nitrous oxide | Vapor | 10024-97-2 | >480 | >480 | 6 | <0.018 | 0.018 | ||||

| Norflurane | Vapor | 811-97-2 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Octane, n- | Liquid | 111-65-9 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Oleum (103% (13% free SO3)) | Liquid | 8014-95-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Oleum (40% free SO3) | Liquid | 8014-95-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Oleum (65% free SO3) | Liquid | 8014-95-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Oxalic acid (10.5%) | Liquid | 144-62-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| PCB (50% in Trichlorbenzene) | Liquid | mix | >480 | >480 | >480 | 6 | 6 | 6 | |||

| Paraphenylene diisocyanate (PPDI) crude | Liquid | 104-49-4 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Pentachlorophenol (sat in Methanol) | Liquid | 87-86-5 | >480 | >480 | >480 | 6 | <0.013 | 0.013 | <6.2 | >480 | 6 |

| Pentanedial, 1,5- (5%) | Liquid | 111-30-8 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Pentanedial, 1,5- (50%) | Liquid | 111-30-8 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Pentene nitrile, 3- | Liquid | 4635-87-4 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Pentene nitrile, cis-2- (70%) | Liquid | 25899-50-7 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Pentyl acetate | Liquid | 628-63-7 | >480 | >480 | >480 | 6 | <0.003 | 0.003 | <1.4 | >480 | 6 |

| Perchloric acid (70%) | Liquid | 7601-90-3 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Perfluoro 2-propoxy propionyl fluoride | Liquid | 2062-98-8 | imm | >480 | >480 | 6 | <0.04 | 0.008 | <19.2 | >480 | 6 |

| Perfluoroethane | Vapor | 76-16-4 | >480 | >480 | 6 | <0.1 | 0.0139 | ||||

| Phenethylene | Liquid | 100-42-5 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Phenol (45 °C, molten) | Liquid | 108-95-2 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Phenol (60 °C, molten) | Liquid | 108-95-2 | 113 | 125 | 165 | 4 | <5 | 0.01 | 736 | 250 | 5 |

| Phenol (85% at 45 °C) | Liquid | 108-95-2 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Phenol (85%) | Liquid | 108-95-2 | >480 | >480 | >480 | 6 | <0.06 | 0.006 | <2.9 | >480 | 6 |

| Phenyl amine | Liquid | 62-53-3 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Phenyl chloride | Liquid | 108-90-7 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Phenyl cyanide | Liquid | 100-47-0 | >480 | >480 | >480 | 6 | <0.004 | 0.004 | <1.9 | >480 | 6 |

| Phenyl ethane | Liquid | 100-41-4 | >480 | >480 | >480 | 6 | <0.005 | 0.005 | <2.4 | >480 | 6 |

| Phenyl ethanol, 1- | Liquid | 98-85-1 | >480 | >480 | >480 | 6 | <0.005 | 0.005 | <2.4 | >480 | 6 |

| Phenyl mercaptan | Liquid | 108-98-5 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Phenyl propane, 2- | Liquid | 98-82-8 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Phenyl trichlorosilane | Liquid | 98-13-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Phosgene | Vapor | 75-44-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Phosphine | Vapor | 7803-51-2 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Phosphor säure trimethylester | Liquid | 512-56-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Phosphoric acid (85%) | Liquid | 7664-38-2 | >480 | >480 | >480 | 6 | <0.18 | 0.18 | <86.4 | >480 | 6 |

| Phosphorus oxychloride | Liquid | 10025-87-3 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Phosphorus trichloride | Liquid | 7719-12-2 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Picoline, 2- | Liquid | 109-06-8 | >480 | >480 | >480 | 6 | <0.024 | 0.024 | <11.5 | >480 | 6 |

| Picoline, 3- | Liquid | 108-99-6 | >480 | >480 | >480 | 6 | <0.024 | 0.024 | <11.5 | >480 | 6 |

| Pimelic ketone | Liquid | 108-94-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Polymethylene polyphenyle isocyanate (p-MDI) | Liquid | 9016-87-9 | >480 | >480 | >480 | 6 | <0.005 | 0.005 | <2.4 | >480 | 6 |

| Potassium acetate (sat) | Liquid | 127-08-2 | >480 | >4808 | >480 | 6 | <0.49 | 0.49 | |||

| Potassium chromate (sat) | Liquid | 7789-00-6 | >480 | >4808 | >480 | 6 | <0.51 | 0.51 | |||

| Potassium hydroxide (45%) | Liquid | 1310-58-3 | >480 | >480 | 6 | <0.1 | 0.008 | ||||

| Prop-2-en-1-al | Liquid | 107-02-8 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Prop-2-yn-1-ol | Liquid | 107-19-7 | >480 | >480 | >480 | 6 | <0.07 | 0.07 | <33.6 | >480 | 6 |

| Propan -2-ol | Liquid | 67-63-0 | >480 | >480 | >480 | 6 | <0.0097 | 0.0097 | <4.7 | >480 | 6 |

| Propan -2-one | Liquid | 67-64-1 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Propargyl alcohol | Liquid | 107-19-7 | >480 | >480 | >480 | 6 | <0.07 | 0.07 | <33.6 | >480 | 6 |

| Propen 1-ol, 2- | Liquid | 107-18-6 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Propenamide (50%) | Liquid | 79-06-1 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Propene acid | Liquid | 79-10-7 | >480 | >480 | >480 | 6 | <0.06 | 0.06 | <28.8 | >480 | 6 |

| Propenenitrile, 2- | Liquid | 107-13-1 | >480 | >480 | >480 | 6 | <0.0003 | 0.0003 | |||

| Propenoic acid butyl ester, 2- | Liquid | 141-32-2 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Propenoic acid nitrile | Liquid | 107-13-1 | >480 | >480 | >480 | 6 | <0.0003 | 0.0003 | |||

| Propylene aldehyde | Liquid | 123-73-9 | >480 | >480 | 6 | <0.1 | 0.006 | ||||

| Propylene dichloride | Liquid | 78-87-5 | >480 | >480 | >480 | 6 | |||||

| Propylene imine (90%) | Liquid | 75-55-8 | 120 | 150 | >480 | 6 | 0.34 | 0.01 | |||

| Propylene oxide, 1,2- | Liquid | 75-56-9 | >480 | >480 | >480 | 6 | <0.0016 | 0.0016 | <0.7 | >480 | 6 |

| Pyridine | Liquid | 110-86-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Pyroacetic ether | Liquid | 67-64-1 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Pyrrolidine | Liquid | 123-75-1 | 407 | 413 | 9.2 | 0.012 | |||||

| Sarin (GB), MIL-STD-282 (10 g/m2) | Liquid | 107-44-8 | >4808 | ||||||||

| Sarin (GB), MIL-STD-282 (100 g/m2) | Liquid | 107-44-8 | >4808 | ||||||||

| Silane | Vapor | 7803-62-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Silicon tetrachloride | Liquid | 10026-04-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Sodium hydroxide (50%) | Liquid | 1310-73-2 | >480 | >480 | >480 | 6 | <0.03 | 0.03 | <14.4 | >480 | 6 |

| Sodium hypochlorite (15%) | Liquid | 7681-52-9 | >480 | >480 | >480 | 6 | <0.03 | 0.03 | <14.4 | >480 | 6 |

| Sodium metabisulphite (38%) | Liquid | 7681-57-4 | >480 | >480 | 6 | <0.052 | 0.052 | ||||

| Sodium methylate (50% in Methanol) | Liquid | 124-41-4 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Soman (GD), MIL-STD-282 (10 g/m2) | Liquid | 96-64-0 | >4808 | ||||||||

| Soman (GD), MIL-STD-282 (100 g/m2) | Liquid | 96-64-0 | >4808 | ||||||||

| Stickoxid | Vapor | 10102-43-9 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Stoddard solvent | Liquid | 8052-41-3 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Styrene | Liquid | 100-42-5 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Sulfamic acid (15%) | Liquid | 5329-14-6 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Sulfamidic acid (15%) | Liquid | 5329-14-6 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Sulfaminsäure (15%) | Liquid | 5329-14-6 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Sulfur Mustard (HD), MIL-STD-282 (10 g/m2) | Liquid | 505-60-2 | >4808 | ||||||||

| Sulfur Mustard (HD), MIL-STD-282 (100 g/m2) | Liquid | 505-60-2 | >4808 | ||||||||

| Sulfur dioxide | Vapor | 7446-09-5 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Sulfur hexafluoride | Vapor | 2551-62-4 | >480 | >480 | 6 | <0.015 | 0.015 | ||||

| Sulfur monochloride | Liquid | 10025-67-9 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Sulfur trioxide | Liquid | 7446-11-9 | 90 | 90 | 90 | 3 | 696 | 0.1 | |||

| Sulfuric acid (>95%) | Liquid | 7664-93-9 | >480 | >480 | >480 | 6 | <0.005 | 0.05 | <24 | >480 | 6 |

| Sulfuric acid diethyl ester | Liquid | 64-67-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Sulfuric acid dimethyl ester | Liquid | 77-78-1 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Sulfuric acid fuming (103% (13% free SO3)) | Liquid | 8014-95-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Sulfuric acid fuming (40% free SO3) | Liquid | 8014-95-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Sulfuric acid fuming (65% free SO3) | Liquid | 8014-95-7 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Sulfuryl chloride | Liquid | 7791-25-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Sulphur dichloride | Liquid | 10545-99-0 | 440 | 440 | >480 | 6 | <0.3 | 0.1 | <48 | >480 | 6 |

| Sulphur dichloride (80%) | Liquid | 10545-99-0 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Tabun (GA), MIL-STD-282 (10 g/m2) | Liquid | 77-81-6 | >4808 | ||||||||

| Tabun (GA), MIL-STD-282 (100 g/m2) | Liquid | 77-81-6 | >4808 | ||||||||

| Tetracarbonylnickel | Liquid | 13463-39-3 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Tetrachloro ethane, 1,1,2,2,- | Liquid | 79-34-5 | >480 | >480 | >480 | 6 | <0.008 | 0.008 | <3.8 | >480 | 6 |

| Tetrachloro ethylene, 1,1,2,2- | Liquid | 127-18-4 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Tetrachloro methane | Liquid | 56-23-5 | >480 | >480 | >480 | 6 | <0.015 | 0.015 | <7.2 | >480 | 6 |

| Tetraethoxysilane | Liquid | 78-10-4 | >480 | >480 | 6 | <0.014 | 0.014 | ||||

| Tetraethyl lead | Liquid | 78-00-2 | >480 | >480 | >480 | 6 | <0.07 | 0.07 | <33.6 | >480 | 6 |

| Tetraethylene pentamine | Liquid | 112-57-2 | 306*/421 | >480 | >480 | 6 | <0.01 | 0.005 | <4.8 | >480 | 6 |

| Tetrafluoroethane, 1,1,1,2- | Vapor | 811-97-2 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Tetrafluoromethane | Vapor | 75-73-0 | >480 | >480 | >480 | 6 | <0.0177 | 0.0177 | <8.5 | >480 | 6 |

| Tetrahydrofuran | Liquid | 109-99-9 | >480 | >480 | >480 | 6 | <0.04 | 0.04 | <19.2 | >480 | 6 |

| Tetramethyl ammonium hydroxide (25%) | Liquid | 75-59-2 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Tetramethyl tin (0.5% in Pentane) | Liquid | 594-27-4 | >480 | >480 | 6 | <0.006 | 0.006 | ||||

| Thioalkohol | Liquid | 75-08-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Thioglycolic acid | Liquid | 68-11-1 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Thionyl chloride | Liquid | 7719-09-7 | 90 | 90 | 90 | 3 | 63.6 | 0.1 | |||

| Thiophenol | Liquid | 108-98-5 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Titan(IV) chloride | Liquid | 7550-45-0 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Titanium tetrachloride | Liquid | 7550-45-0 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Toluene | Liquid | 108-88-3 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Toluene diisocyanate, 1,3- | Liquid | 26471-62-5 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Toluene diisocyanate, 2,4- | Liquid | 584-84-9 | >480 | >480 | >480 | 6 | <0.0216 | 0.0216 | <13.5 | >480 | 6 |

| Toluene diisocyanate, 2,4- (80%) | Liquid | 584-84-9 | >480 | >480 | >480 | 6 | <0.0281 | 0.0281 | <13.5 | >480 | 6 |

| Toluidine, o- | Liquid | 95-53-4 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Trichloro 1,2,2-trifluoroethane, 1,1,2- | Liquid | 76-13-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Trichloro 1,3,5-triazine, 2,4,6- (20% in Toluene) | Liquid | 108-77-0 | >480 | >480 | >480 | 6 | <0.10 | 0.1 | <48 | >480 | 6 |

| Trichloro benzene, 1,2,4- | Liquid | 120-82-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Trichloro ethane, 1,1,1- | Liquid | 71-55-6 | >480 | >480 | >480 | 6 | <0.004 | 0.004 | <1.9 | >480 | 6 |

| Trichloro ethane, 1,1,2- | Liquid | 79-00-5 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Trichloro ethanol, 2,2,2- | Liquid | 115-20-8 | >480 | >480 | >480 | 6 | <0.008 | 0.008 | <3.8 | >480 | 6 |

| Trichloro ethylene | Liquid | 79-01-6 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Trichloro methane | Liquid | 67-66-3 | >480 | >480 | >480 | 6 | <0.0037 | 0.0037 | <1.7 | >480 | 6 |

| Trichloro phenylsilane | Liquid | 98-13-5 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Trichloro silane | Liquid | 10025-78-2 | >480 | >480 | 6 | <0.0218 | 0.0218 | ||||

| Triethyl amine | Liquid | 121-44-8 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Triethylentetramine (60%) | Liquid | 112-24-3 | >480 | >480 | >480 | 6 | <0.005 | 0.005 | <2.4 | >480 | 6 |

| Trifluoro 2-(trifluoromethyl)propene, 3,3,3- | Vapor | 382-10-5 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Trifluoro ethanol, 2,2,2- | Liquid | 75-89-8 | >480 | >480 | >480 | 6 | <0.0013 | 0.0013 | <0.6 | >480 | 6 |

| Trifluoro methane | Vapor | 75-46-7 | >480 | >480 | 6 | <0.0141 | 0.0141 | ||||

| Trifluoro methansulfonic acid | Liquid | 1493-13-6 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Trimethyl amine | Vapor | 75-50-3 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Trimethyl aminomethane | Liquid | 75-64-9 | >480 | >480 | >480 | 6 | <0.03 | 0.03 | <14.4 | >480 | 6 |

| Trimethyl phosphate | Liquid | 512-56-1 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Trimethyl phosphite | Liquid | 121-45-9 | >480 | >480 | >480 | 6 | <0.02 | 0.02 | <9.6 | >480 | 6 |

| Tripropyl amine | Liquid | 102-69-2 | >480 | >480 | >480 | 6 | <0.07 | 0.07 | <33.6 | >480 | 6 |

| Tungsten hexafluoride | Vapor | 7783-82-6 | >480 | >480 | 6 | <0.0259 | 0.0259 | ||||

| VM & P Naphtha | Liquid | 8030-30-6 | >480 | >480 | >480 | 6 | <0.0201 | 0.0201 | <9.6 | >480 | 6 |

| VX Nerve Agent, MIL-STD-282 (10 g/m2) | Liquid | 50782-69-9 | >4808 | ||||||||

| VX Nerve Agent, MIL-STD-282 (100 g/m2) | Liquid | 50782-69-9 | >4808 | ||||||||

| Vinyl acetate | Liquid | 108-05-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Vinyl benzol | Liquid | 100-42-5 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Vinyl carbinol | Liquid | 107-18-6 | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Vinyl chloride | Vapor | 75-01-4 | >480 | >480 | >480 | 6 | <0.001 | 0.001 | <0.48 | >480 | 6 |

| Vinyl cyanide | Liquid | 107-13-1 | >480 | >480 | >480 | 6 | <0.0003 | 0.0003 | |||

| Vinyl ethylene (0 °C, liquid) | Liquid | 106-99-0 | >180 | >180 | >180 | 4 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Vinyl ethylene (gaseous) | Vapor | 106-99-0 | >480 | >480 | >480 | 6 | <0.05 | 0.05 | <24 | >480 | 6 |

| Vinyl magnesium chloride (16.5% in Tetrahydrofuran) | Liquid | 3536-96-7 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| Vinylidene chloride | Liquid | 75-35-4 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| White Liquor | Liquid | mix | >480 | >480 | >480 | 6 | <0.1 | 0.1 | <48 | >480 | 6 |

| Xylene, mixed isomers | Liquid | 1330-20-7 | >480 | >480 | >480 | 6 | <0.01 | 0.01 | <4.8 | >480 | 6 |

| m-Cresol 55%, p-Cresol 30%, Phenol 15% (mix) | Liquid | mix | >480 | >480 | >480 | 6 | <0.09 | 0.09 | <43.2 | >480 | 6 |

| t-Sodium-amylate / t-amyl alcohol (mix) | Liquid | mix | 120 | 120 | 240 | 5 | 4.9 | 0.01 |

SPECIAL WARNINGS

- *CAUTION: This information is based upon technical data that DuPont believes to be reliable. It is subject to revision as additional knowledge and experience are gained. DuPont makes no guarantee of results and assumes no obligation or liability in connection with this information. It is the user's responsibility to determine the level of toxicity and the proper personal protective equipment needed. The information set forth herein reflects laboratory performance of fabrics, not complete garments, under controlled conditions. It is intended for informational use by persons having technical skill for evaluation under their specific end-use conditions, at their own discretion and risk. Anyone intending to use this information should first verify that the garment selected is suitable for the intended use. In many cases, seams and closures have shorter breakthrough times and higher permeation rates than the fabric. Please contact DuPont for specific data. If fabric becomes torn, abraded or punctured, or if seams or closures fail, or if attached gloves, visors, etc. are damaged, end user should discontinue use of garment to avoid potential exposure to chemical. Since conditions of use are outside our control, we make no warranties, express or implied, including, without limitation, no warranties of merchantability or fitness for a particular use and assume no liability in connection with any use of this information. This information is not intended as a license to operate under or a recommendation to infringe any patent or technical information of DuPont or others covering any material or its use.

Cellosolve® and Selexol™ are registered trademarks of Dow Chemicals Company. Skydrol® is a registered trademark of Solutia. - *CAUTION: This information is based upon technical data that DuPont believes to be reliable. It is subject to revision as additional knowledge and experience are gained. DuPont makes no guarantee of results and assumes no obligation or liability in connection with this information. It is the user's responsibility to determine the level of toxicity and the proper personal protective equipment needed. The information set forth herein reflects laboratory performance of fabrics, not complete garments, under controlled conditions. It is intended for informational use by persons having technical skill for evaluation under their specific end-use conditions, at their own discretion and risk. Anyone intending to use this information should first verify that the garment selected is suitable for the intended use. In many cases, seams and closures have shorter breakthrough times and higher permeation rates than the fabric. Please contact DuPont for specific data. If fabric becomes torn, abraded or punctured, or if seams or closures fail, or if attached gloves, visors, etc. are damaged, end user should discontinue use of garment to avoid potential exposure to chemical. Since conditions of use are outside our control, we make no warranties, express or implied, including, without limitation, no warranties of merchantability or fitness for a particular use and assume no liability in connection with any use of this information. This information is not intended as a license to operate under or a recommendation to infringe any patent or technical information of DuPont or others covering any material or its use.

Cellosolve® and Selexol™ are registered trademarks of Dow Chemicals Company. Skydrol® is a registered trademark of Solutia. - As of January 2023, all DuPont Personal Protection products are manufactured under specifications that exclude components containing natural rubber latex. Tyvek® 500, Tyvek® 600 and Tyvek® 800 styles made before January 2023 contain natural rubber latex, which may cause allergic reactions in some sensitized individuals. Anyone who begins to exhibit an allergic response during the use of DuPont products should immediately cease using these products and should report it to DuPont at +1 (888) 439-2988 so that an investigation can be initiated.