IC501B option 0B

Tyvek® IsoClean®

DuPont™ Tyvek® IsoClean® Sleeve. Bound Seams. Covered Elastic at Both Ends. 18"" Long. White.

DUPONT™ SAFESPEC™ Terms of Use

Product Selector Agreement

The following information must be read and accepted by the user before proceeding.

The DuPont™ SafeSPEC™ Product Selector Tool (“Tool”) is intended to assist in choosing protective clothing styles for particular applications and does not replace the judgment of a qualified safety professional or industrial hygienist. Additional personal protective equipment (“PPE”), such as but not limited to: respiratory, eye, head, foot, and hand protection, may be required. Supplying the proper hazard/chemical and exposure information for your hazard scenario is critical in order to obtain suggestions of possible garment options for your consideration. Inaccurate information could result in improper suggestions. Since there are other factors involved which could affect the final PPE decision and may not be considered in this Tool, the final decision on protective clothing selection is the responsibility of the buyer, safety professional, industrial hygienist and end-user. DuPont de Nemours, Inc. or its affiliates DISCLAIM ANY RESPONSIBILITY OR LIABILITY FOR ANY INFORMATION OR SUGGESTIONS PROVIDED BY THE TOOL OR THE USE THEREOF.

WARNING / CAUTION

There are uses, environments and chemicals for which any garment will be unsuitable. It is the responsibility of the user to review available data and verify that the garment selected is appropriate for the intended use and meets all specified government and industry standards.

Search by :

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 1 of 3

You may enter from one to five chemicals or other hazards that may be present in your working environment. Our tool will find the best product match for the combined hazards. Enter a single chemical or hazard if you wish to find the best possible product match for that one hazard.

Chemical or Other Hazard Name

or

CAS Number

| Chemical Details | CAS | Actions |

|---|

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 2 of 3

CHEMICAL COMPARISON

The table below shows the Normalized Breakthrough times of fabrics for the hazards selected. (Testing Details) You can find specific garments that protect against these hazards by clicking the 'Next' button below.

Done

Done

Done

|

|

|

|

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

Step 3 of 3

1 Choose Hazards

1 Enter

Chemicals

2 View Permeation Data

2 View

Data

3 View Matching Products

3 View

Products

step3of3

Is Suitable For Hazard Scenario

Is Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

| Hazard | Fabric/Materials | Seam | Design |

|---|

Is Suitable For Hazard Scenario

Is Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

Is Not Suitable For Hazard Scenario

| Hazard | Fabric/Materials | Seam | Design |

|---|

Technical Data Sheet

FEATURES & PRODUCT DETAILS

Tyvek® IsoClean® delivers an ideal balance of protection, durability and comfort. Made using a patented flash spinning process, Tyvek® provides an inherent barrier to particles, microorganisms and non-hazardous light liquid splash.

- Bound seams are covered with garment fabric to reinforce the seam and to reduce the potential for particle penetration

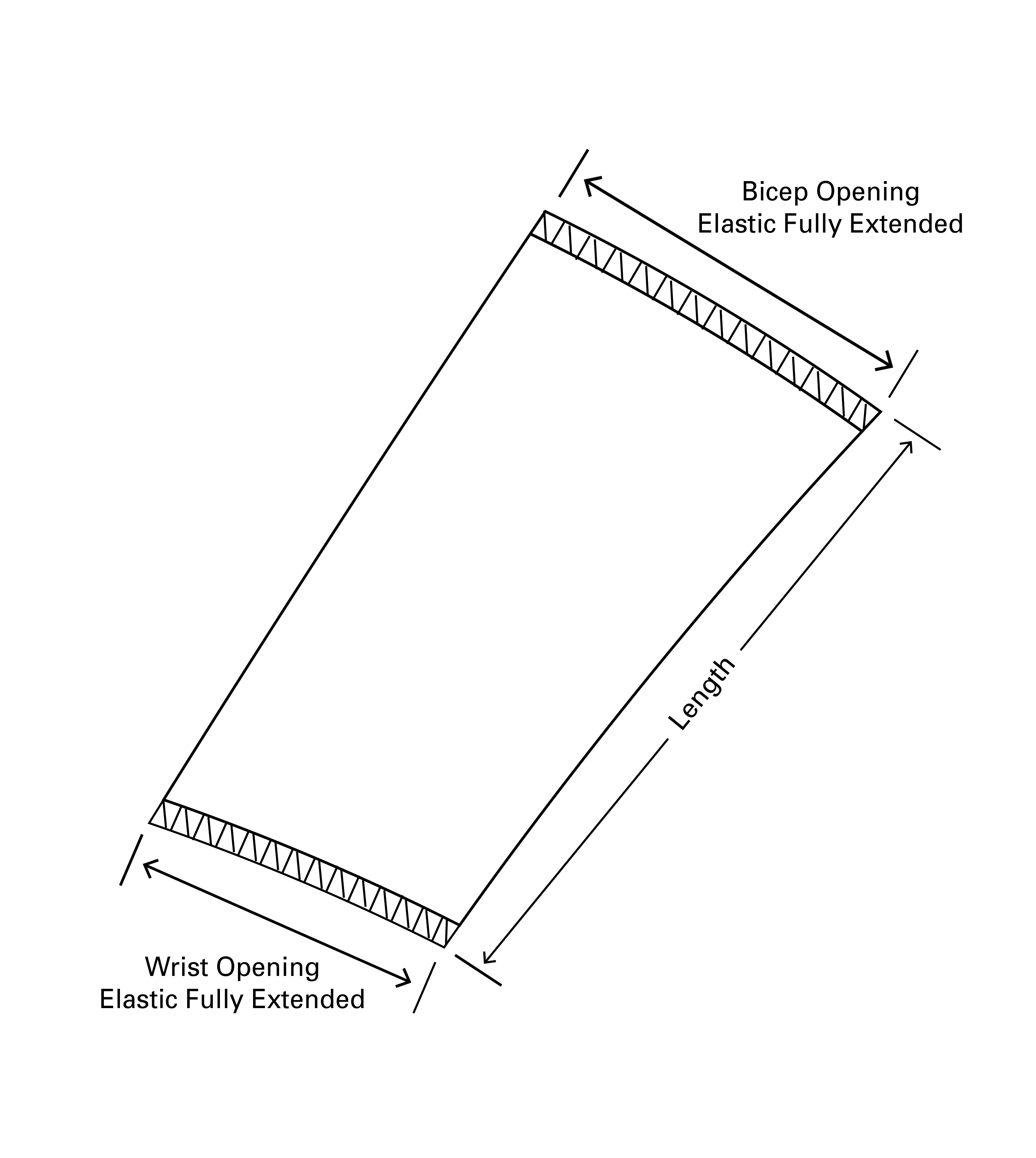

- Elastic at both ends (bicep and wrist) for arm protection

- 18" long

- One size fits most

- Bulk packaged in double transparent poly liners

AVAILABLE OPTIONS

FINISHED DIMENSIONS

ADDITIONAL EQUIPMENT NEEDED

Fabric & Permeation/Penetration Data

Physical Properties

Data relating to mechanical performance of the fabrics used in DuPont chemical protective clothing, listed for the selected garment according to the test methods and relevant European standard, if applicable. Such properties, including abrasion and flex-cracking resistance, tensile strength and puncture resistance can help in the assessment of protective performance.

| Property | Test Method | Typical Result | stdDev |

|---|---|---|---|

| Basis Weight | ASTM D3776 | 1.22 oz/yd2 | 0.04 oz/yd2 |

| Burst Strength - Mullen | ASTM D774 | 54 psi | 11 psi |

| Breaking Strength - Grab (MD) | ASTM D5034 | 18 lbf | 2 lbf |

| Breaking Strength - Grab (CD) | ASTM D5034 | 23 lbf | 3 lbf |

| Bacterial Filtration Efficiency (3.0 micron) | ASTM F2101 | 99.0 % | 0.5 % |

| Hydrostatic Head | AATCC 127 | 91 cm H2O | 14 cm H2O |

- According to EN 14325

- According to EN 14126

- According to EN 1073-2

- According to EN ISO 14116

- According to EN ISO 11612

- Front Tyvek ® / Back

- Based on test according to ASTM D-572

- See Instructions for Use for further information, limitations and warnings

- Larger than

- Smaller than

- Smaller than or equal to

- Not Applicable

- Standard Deviation